Today we launched our 1200 gram balloon from Mt. Greylock State Reservation in Lanesborough, MA. We launched right near the visitors center, in a big field.

We started the day by loading everything into my car, while the other cars took the passengers. Here’s a picture to show you how crowded it was.

It took us about 3 hours to convoy out there, and I insisted that we stop for coffee because many of us were running on very little sleep. We arrived at the launch site around 11:30 am, and started the process of assembling everything.

Nate started filling the balloon while Fjodor and I worked on assembling the payload packages. I turned on the cameras and started the script (which takes pictures every 5 seconds automatically) and the Arduino to start logging temperatures.

Fjodor worked on testing our communication systems via aprs.fi, and everything worked out. We assembled everything and launched around 1:25 pm. Jean started the cutoff mechanism right around 1:10, so 3:17 would be the time where the mechanism starts cutting through the rope and releasing it from the balloon.

Here’s a video of the actual launch!

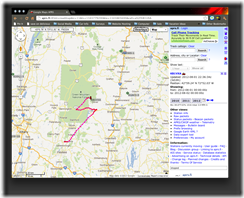

We were using our smartphones and Nate’s callsign to track where the balloon was in real time by using aprs.fi It worked out great, and we received signal that it reached 95,000 feet and landed in Dover, Vermont.

We ended up tracking it into the woods, and found the Balloon, but it was in a tree. We didn’t have a way of getting it down, so we had to leave it there and regroup. It ended up being right off of VAST trails in Vermont, which are public land, and it was high up in a tree that we weren’t worried about something happening to the balloon.

On the ride home, we formulated a plan using a bow and arrow attached to fishing line. If we shot that over, we could tie rope to where the arrow was, and pull a heavier duty string over the tree to pull it down. We stopped in Gardner, MA, where I grew up, and picked up my bow and arrow, with the though of going back out tomorrow to retrieve our payloads.